Specialization in Reverse Engineering, Manufacture and develop various components and parts for underground earth moving equipment to OEM specifications.

Fabrication of pins and bushes to mainframes.

High quality Facility which boasts a global standard of Machinery and skills for re-engineering components for all OEM specifications.

Our well-equipped workshop can handle any rebuild request. Competent tradesmen will handle your equipment as our own. Buckets, Cabs and Cylinders refurbishment are only a small portion of what we have to offer. All our work is done according to OEM specifications.

Supply of all types of fittings and hoses to customers and run complete hydraulic workshop consisting of consignment stock, crimping machine, and trained hose technician.

We source and supply quality parts from OEM.

▪ Complete Installation

▪ Maintenance

▪ Supply all related components

▪ Project management

▪ Turnkey conveyor projects and maintenance

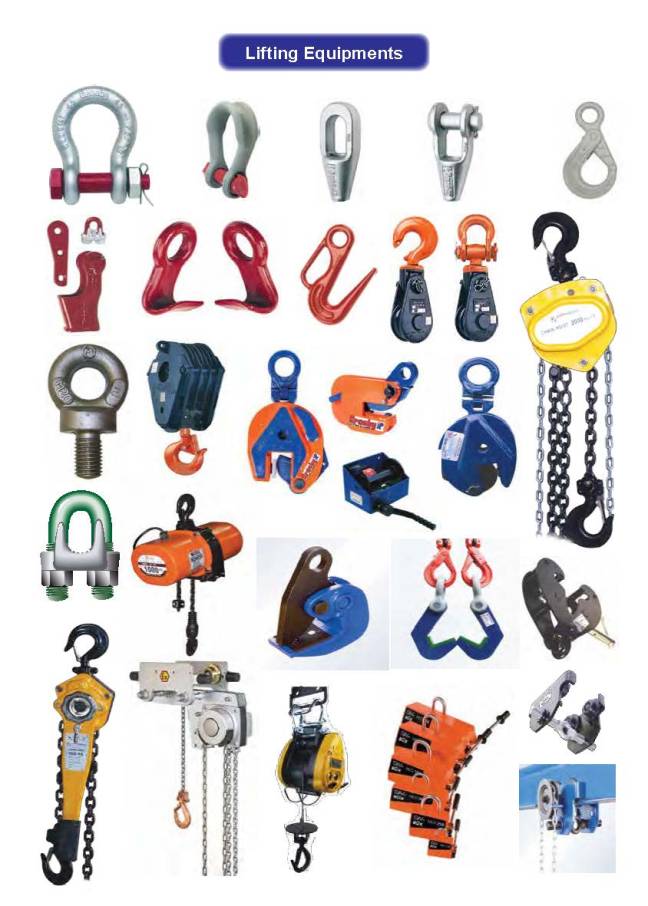

Our well-trained certified tradesman will do on site load tests and repairs to any overhead crane / lifting equipment / forklifts.

We also trade in various brands of lifting equipment.

▪ Project management

▪ Complete contract mining projects

Supply and repairs on all brands of pumps to OEM specifications.

Khaya specialises in distribution of DBY diaphragm pumps.

We supply and repair an entire range of mechanical and electrical valves.

MAINTENANCE PIPELINES / INSTALLATIONS

Installation of complete pipelines on surface and underground.

Khaya Engineering provides maintenance of the entire plant system, manufacture and supply spares of the float thickener, gearbox, bearing units, pulleys, plumber blocks and pump spare.

- Maintenance on all plants-float and thickener section.

- Supply all mechanical components.

- 24/7 Breakdown service.

- Mechanical fabrication (structural).

- Product improvement.

- Projects.

- Work on conveyor belts - replace of idlers, pulleys, and plumber blocks.

Operational reports

- Receiving operator reports.

- Monitor cost for each vehicle.

- Monitor downtime on an individual and fleet basis. (Availability/Utilization)

- Report on performance on monthly basis.

- Perform regular equipment condition reports and make corrective recommendation.

- Report on breakdowns and unscheduled repairs

- Record all Lub- L/Ton.

- Monitor driving practices.

Costs and controls

- Cost control on spares/ Repairs Procedure Standardization of store systems.

- Record keeping on tyres R/Ton.

- Damage control investigations.

Maintenance

Once the planned maintenance schedules and times have been set down and approved no mining official shall overrule the responsible engineer.

Planned Maintenance = Daily, Weekly, Monthly, Quarterly, and yearly scheduled maintenance activities shall be drawn up per equipment type.

- Planned Maintenance.

- Planned Maintenance Schedule.

- Missed Services.

- Monthly Reports.

- Standard for determine the efficiency.

The drivetrain is the part of a machine which connects the engine and transmission to the wheel axles.

All repairs to any drive train component will be done to OEM specifications and tested by a 3rd party to ensure quality workmanship.